Nu Drain

Nu Drain is a non-destructive, patent-protected structural lining process from Nu Flow.

Where can Nu Drain be used?

- Mains, Horizontal Laterals, Vertical Stacks

- Sanitary Systems

- Storm/Roof Drains

- Vent Systems

- Other Waste Systems

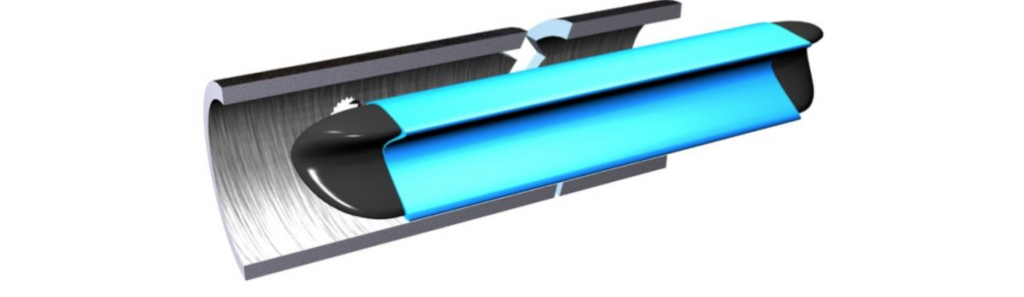

There are two installation techniques for CIPP:

1) Inversion which follows the design standards of ASTM F1216 and

2) Pull-in-Place which follows the installation methods of ASTM F1743 and the design standards from ASTM F1216.

This innovative approach to CIPP lining makes it a preferred solution for rehabilitating deteriorated drain systems with minimal disruption.

What makes Nu Drain unique is that the patented internal bladder system is made with rubber, which allows great versatility and control when dealing with complex bends and pipe configurations (i.e. 90 degree bends). Nu Drain can navigate up to 270 degrees of bends before requiring more direct access to the drainage system.

For property owners exploring options for pipe restoration, this form of trenchless sewer line replacement in Toronto offers a durable, cost-effective alternative to traditional excavation methods.

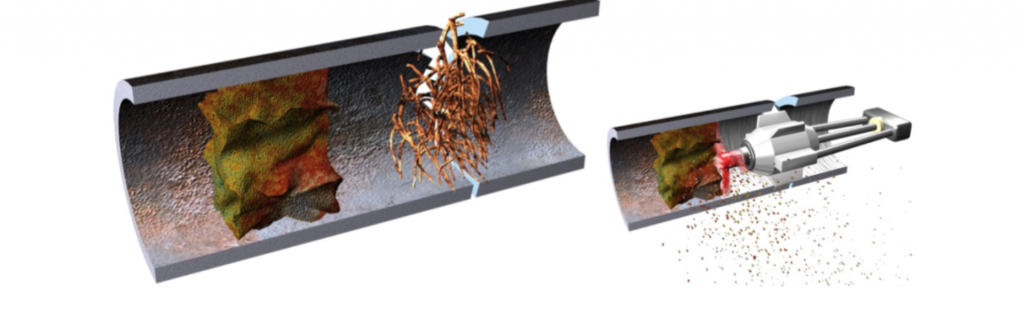

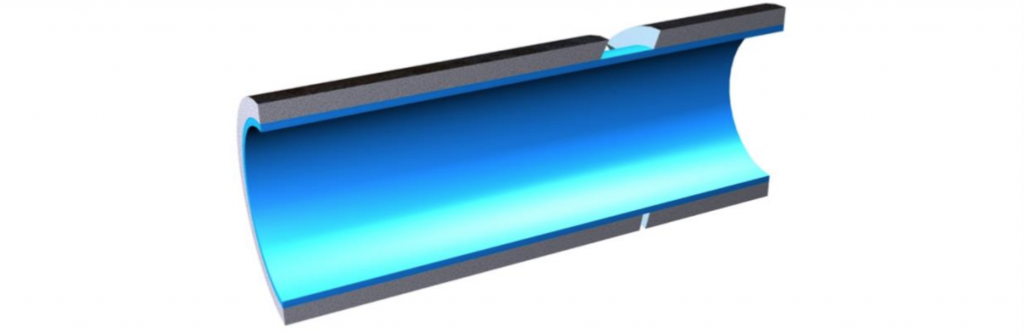

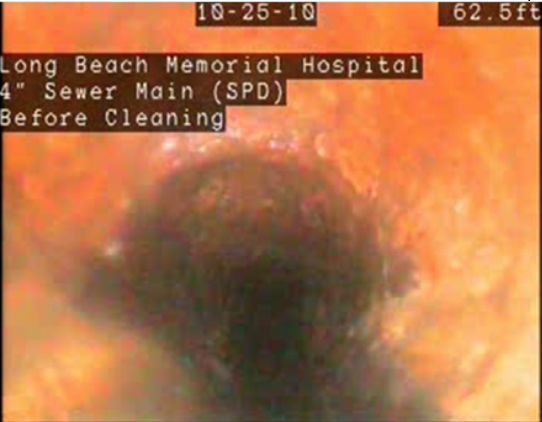

The cured-in-place pipe (CIPP) restoration process restores old and corroded piping systems without the labour of removing the entire pipes, allowing you to save on labour costs while ensuring the longevity of your piping systems. With no digging and destruction of the building required, this means less downtime, displacement or distraction to worry about, so it’s business as usual for you!

Nu Drain has been approved for restoring piping systems made from clay, concrete, metal, iron steel, PVC and fiberglass, and is best suited for pipes that are 1.5“ to 12” in diameter.