The Best Practices for Condo Pipe Maintenance

We frequently encounter the same problem in condominiums across Ontario: Property Managers are experiencing ongoing backups and drainage issues in their pipes, despite regular flushing and costly, labour-intensive repairs. This begs the questions: why aren’t Property Managers and Condominium Corporations exploring long-term methods to reduce capital costs when sanitary and storm plumbing systems need to […]

Case Study: 1441 Lawrence St E

At an aging apartment building in North York, Ontario Pipe Lining cleaned, repaired, and lined 10 thinning and clogged copper kitchen stacks to avoid a full building re-pipe. Project: The third-party property manager had been dealing with costly kitchen stack back-ups and drain clogs on an ongoing basis, resulting in regular inconveniences for apartment residents. […]

The FAQs of Pipe Lining: What You Need to Know

1. What types and sizes of pipes does OPL line? We can camera, clean, and re-line any horizontal or vertical storm or sanitary drain from 1.5 to 12 inches in diameter including vertical sanitary stacks, horizontal sewer lines, mains, and roof drain systems and more. Our clients include residential buildings (condos, apartments, houses), commercial and […]

Predict Emergency Repairs Before They Happen With Video Assessments

Are you running your building’s sanitary and storm piping systems to fail because there are no viable solutions on the market? Traditionally, individual pipe sections would be replaced as they become clogged, corroded or unusable. What if there was a way to change that mindset and take a proactive approach to pipe repair? What if […]

Case Study: Ernest C. Drury School

For the E.C. Drury School in Milton, Ontario, Ontario Pipe Lining mechanically cleaned, lined, and restored a 150 ft-long corroded pipe system using Nu Flow technology. Project: E.C. Drury’s pipes were heavily backed up with calcite, causing water to flood onto the building’s new roof. The school’s roofing engineer believed Nu Flow’s Nu Drain product […]

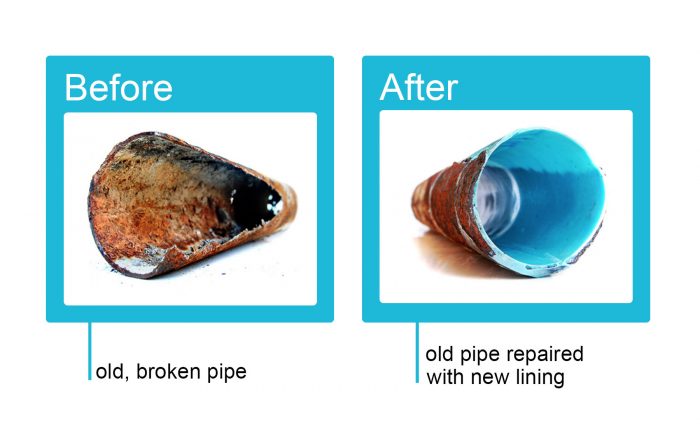

Trenchless Piping Technology and CIPP: A Proactive Solution to Pipe Repair

Pipe repair has traditionally been a reactive, costly, time consuming, and destructive procedure. What many don’t know is that there is a viable, economical, and proactive alternative. Trenchless or CIPP (cured-in-place-pipe) technology is more resilient, safe, versatile, and cost effective than traditional plumbing methods. It is nearly disruption and destruction-free, allowing damaged pipes or end-of-life […]

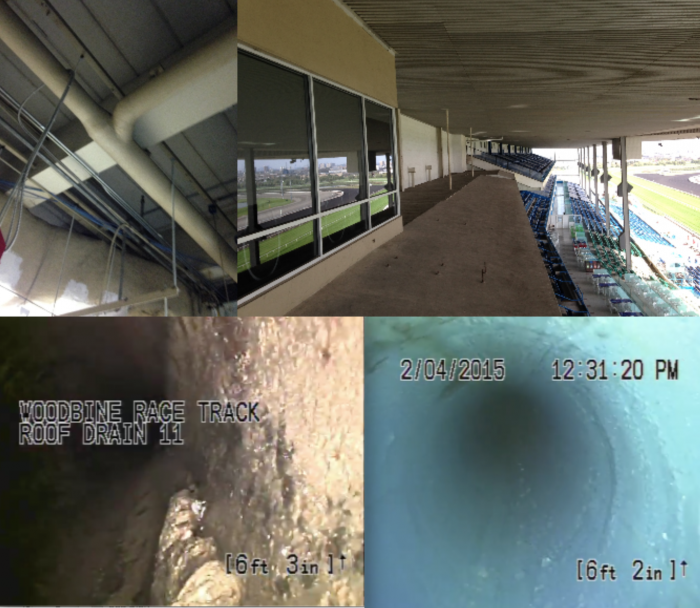

Case Study: Woodbine Grandstand- Roof Drains

“The support, planning in advance and execution in the field and the follow up was unparalleled.” – Chris Edge – Senior PM StratEdge Management Situation A very challenging project that involved inaccessible pipes, working at heights and engineering challenges. 50-year-old storm drains continually leaked onto the grandstand seating. Traditional repair methods were not affordable. Benefits […]

Case Study: Automotive Manufacturer

Situation: An automotive manufacturer in Alliston was challenged with aging sanitary drains that often leaked. The gang-trapped floor drains body were separating from the slab and continually leaking Each leak would effect the production line below and the shut down would cost thousands of dollars per occurrence. We stopped the leaks between slab and drain savings thousands of dollars Benefits […]