The Best Practices for Condo Pipe Maintenance

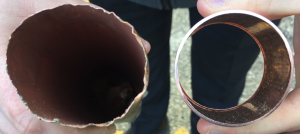

We frequently encounter the same problem in condominiums across Ontario: Property Managers are experiencing ongoing backups and drainage issues in their pipes, despite regular flushing and costly, labour-intensive repairs.

This begs the questions: why aren’t Property Managers and Condominium Corporations exploring long-term methods to reduce capital costs when sanitary and storm plumbing systems need to be replaced?

The reality is, the majority of Property Managers don’t have a roadmap for replacing their plumbing systems. Although critical sanitary and storm systems are just as important as roofs, windows, or other building systems, they are not accurately budgeted for and are often run to fail.

If you are a Property Manager, you may be wondering:

- “Where do I start?”

- “How can I proactively approach pipe repair and save costs?”

- “Do I need to build a maintenance plan?”

These are all questions we commonly receive from clients. To help get you thinking long-term, we’ve answered these questions and more by outlining a few steps you should be taking to prepare for the future replacement of your building’s sanitary and storm systems.

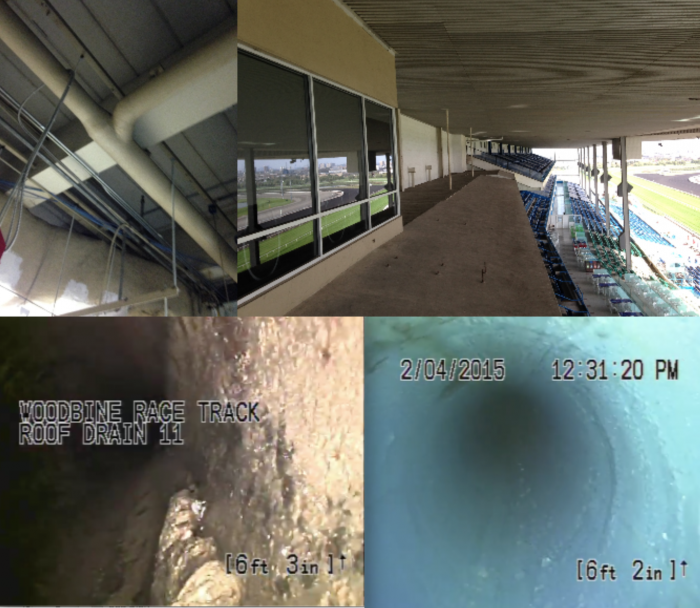

1. Request a recording of the drain that backed up.

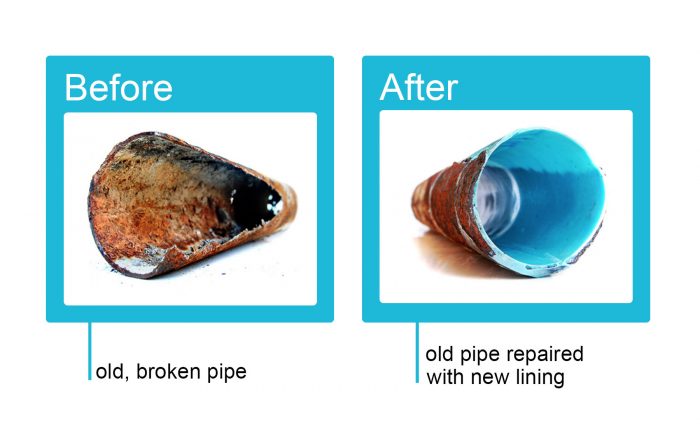

If you are experiencing regular plumbing failures or backups, ensure your contract plumber has the ability to record video footage of the problem before and after it has been cleared. Although plumbing contractors are often skilled at removing blockages or flushing a line, if they are not taking before and after video footage, it is difficult to pinpoint the cause of the backup. Be prepared to pay extra for this recording, but the footage can be shared with OPL to review on a complimentary basis.

This video footage will help to eliminate guesswork, identify drains that need increased maintenance, or to reveal larger problems that could otherwise lead to unbudgeted emergency repairs. If your stacks or horizontal mains aren’t undergoing frequent repair, video assessments are still a proactive, cost-effective measure that should be taken on an annual basis at the very least.

2. When stacks are flushed, request the exact scope of work.

The best way to stay on top of problematic stacks is by keeping track of old statements of work. Ask your contract plumber to outline what stacks were flushed, how many feet were flushed, and where the stacks were accessed (unit numbers, floor, etc). Be sure to keep track of backup history, maintenance work, and flushing dates. It’s also useful to use drawings or blueprints to track cleanouts and repairs in specific buildings or suites and cross-reference back to stack numbers (ie 07, 02 stack etc.)

This documentation streamlines the condition assessment process and gives our technicians an understanding of the current state of your building, its history, and which stacks require scheduled maintenance. Similar to video assessments, it will allow us to spend less time investigating the issue and more time on the repair itself.

3. Look beyond kitchen stack maintenance.

Don’t neglect the other pipe systems in your building. We understand kitchen stacks have the most problems and require frequent maintenance, but it’s important to at least have video footage and documentation of your other pipe systems. Allocate a small amount of your yearly budget to maintaining and assessing each of the stacks in your building. This includes: vent stacks, laundry, toilet, and other wet stacks, storm stacks and lateral mains.

4. Start building a maintenance plan.

At OPL, we focus on being proactive rather than reactive. This means that we want to work with you to conduct regular condition assessments, build an ongoing, sustainable maintenance plan, and ensure reserve funds are spent as efficiently as possible.

Our goal is to predict emergency repairs before they happen, and a condition assessment is the ideal place to start. For more information on condo pipe maintenance or to schedule your condition assessment, get in touch today.